Simple Tips to Modernize Your Factory

In today’s fast-paced industrial landscape, staying competitive requires constant innovation and modernization. If you’re looking to enhance productivity, efficiency, and overall performance in your factory, implementing modern techniques and technologies is crucial. Here are some simple tips to help you modernize your factory and stay ahead of the curve.

Embrace Automation

Automation plays a significant role in modernizing factories, so turning to conveyor belt manufacturers for modern equipment can be a go-to solution. Integrate automated systems and machinery to streamline repetitive tasks, reduce human error, and boost efficiency. Consider implementing robotics and artificial intelligence (AI) to handle routine operations, such as assembly lines, packaging, and material handling. Automation not only improves productivity but also allows your workforce to focus on more complex tasks that require human expertise.

Upgrade Your Machinery

Outdated machinery can hinder productivity and compromise the quality of your products. Evaluate your current equipment and identify areas that need improvement. Then, invest in advanced machinery and tools that offer better performance, energy efficiency, and reliability. Upgrading your machinery can help optimize production processes, reduce downtime, and enhance overall output.

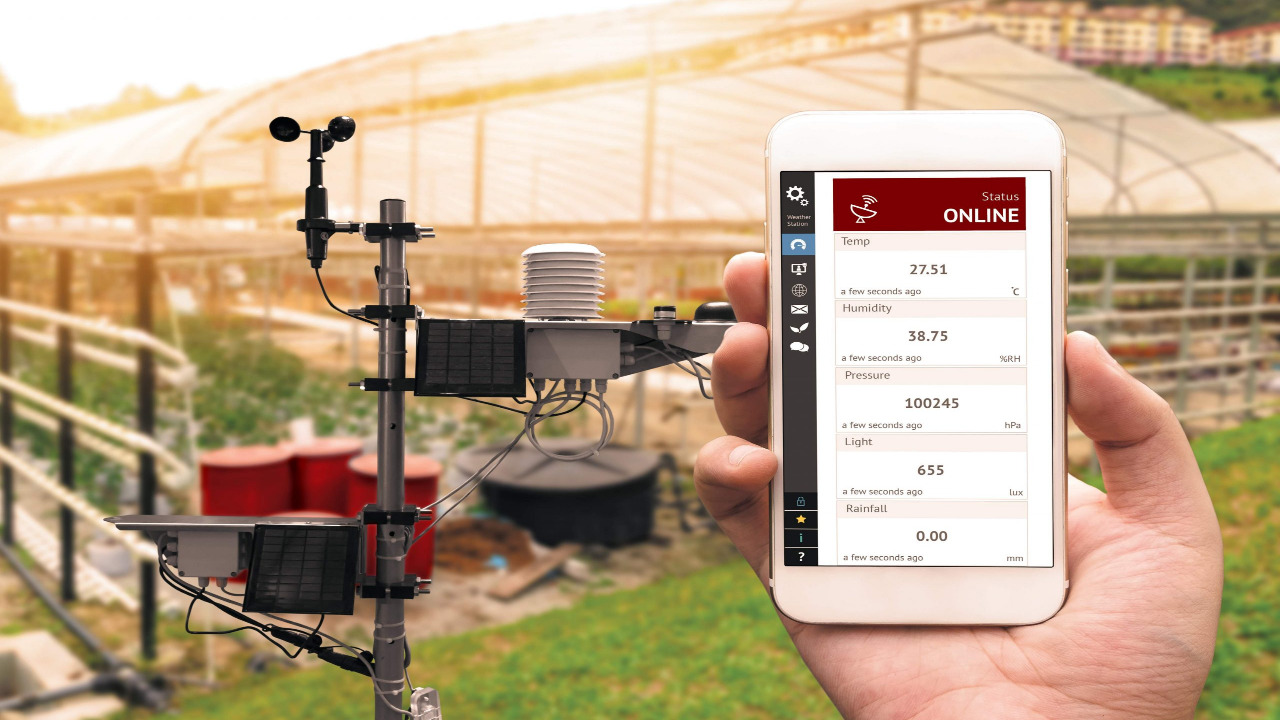

Implement Real-Time Monitoring

Real-time monitoring is essential for proactive decision-making and minimizing downtime. Install sensors, IoT devices, and data analytics systems to monitor various aspects of your factory, including equipment health, energy consumption, and quality control. By analyzing real-time data, you can identify bottlenecks, predict maintenance requirements, and make informed decisions to optimize operations and improve overall efficiency.

Embrace Lean Manufacturing Principles

Lean manufacturing principles focus on eliminating waste, increasing efficiency, and improving product quality. Implement lean manufacturing techniques such as just-in-time (JIT) inventory management, value stream mapping, and continuous improvement practices. By optimizing workflows and reducing waste, you can reduce costs, enhance productivity, and provide better products to customers.

Enhance Connectivity and Communication

Effective communication and connectivity are crucial for seamless operations in a modern factory. Implement an integrated system that connects various departments, machines, and personnel. This could include adopting a Manufacturing Execution System (MES) to track production progress, a centralized data management system for sharing information, and collaboration tools for effective communication. Improved connectivity facilitates coordination, reduces delays, and enhances overall efficiency.

Invest in Employee Training

Modernizing your factory is not just about technology; it also involves upskilling and training your workforce. Invest in comprehensive training programs to ensure your employees are well-versed in the latest technologies and processes. Training can help your employees adapt to change, improve their skills, and contribute to modernization efforts. Empowered and knowledgeable employees can drive innovation and productivity within your factory.

Embrace Sustainable Practices

Sustainability is a growing concern in the industrial sector. Modernize your factory by implementing sustainable practices. This includes adopting energy-efficient machinery, optimizing resource consumption, and implementing waste management systems. Incorporating renewable energy sources like solar or wind power can help reduce your factory’s carbon footprint and lower operating costs.

Continuous Evaluation and Improvement

Modernization is an ongoing process, and it’s essential to continuously evaluate and improve your factory’s operations. Regularly assess your systems, processes, and technology to identify areas for enhancement. Solicit feedback from employees and customers to gain valuable insights. By continuously evaluating and improving your operations, you can stay agile, adapt to changing market demands, and remain at the forefront of the industry.

In conclusion, modernizing your factory is crucial for staying competitive in today’s fast-evolving industrial landscape. By embracing automation, upgrading machinery, implementing real-time monitoring, adopting lean manufacturing principles, enhancing connectivity and communication, investing in employee training, embracing sustainable practices, and continuously evaluating and improving your operations, you can drive productivity, efficiency, and success in your factory.